Thermo-welded bellows for linear rails

Thermo-welded bellows protections for Linear Rails

The cutting precision of the PVC supports allows a precise slide holding and the range of materials used are characteristics that make PEI bellows widely used in all industrial sectors.

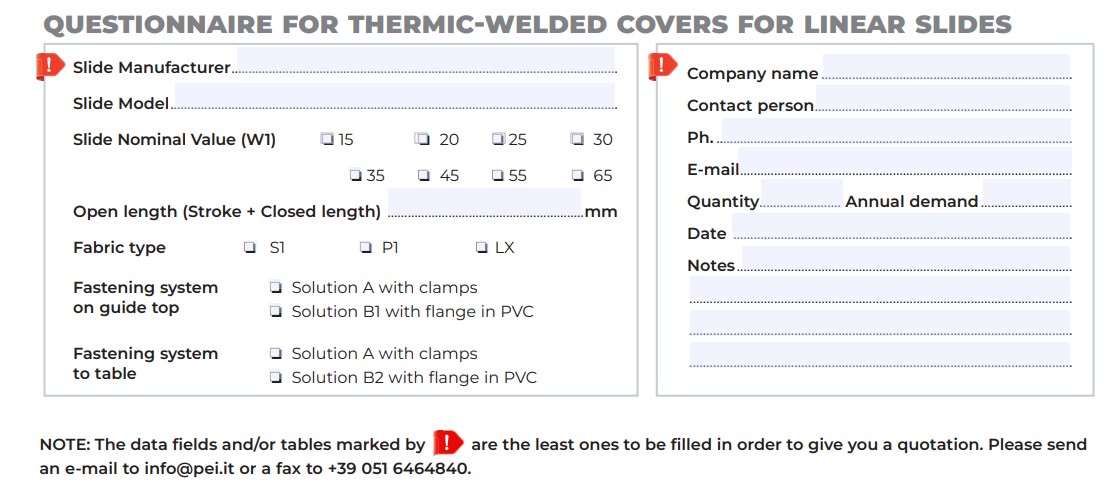

Data

Data

Thermic-welded bellows for linear slides

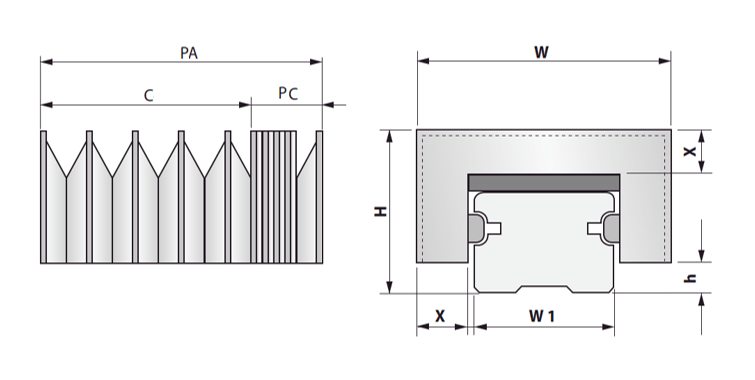

Example of bellows mounted on linear slides

PA = Open Length

C = Stroke

PC = Closed Length

| Standard bellows dimensions for linear slides | |||

| Rail nominal value W1 | Fold height X | Total height H | Rail offset h |

| 15 | 19 | 36 | 5 |

| 20 | 19 | 40,5 | 5 |

| 25 | 19 | 43 | 7,5 |

| 30 | 19 | 51 | 8 |

| 35 | 19 | 51 | 9 |

| 45 | 19 | 61 | 10 |

| 55 | 25 | 73 | 15 |

| 65 | 32 | 90 | 15 |

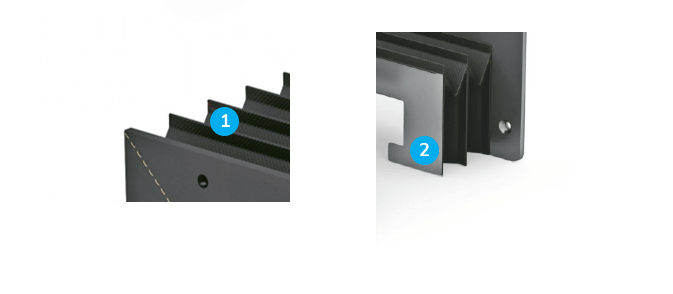

Materials

Bellows materials for linear rails

| Standard materials for linear slides Bellows | |||

| Type of material | Support | Bellows | Closed length for 1000 mm of Open length |

| S1 | PVC 0,5 | PVC + Polyester + PVC 0,25 (TEMAT020) | 90 |

| P1 | PVC 0,5 | Polyurethane + Polyester + Polyurethane 0,25 (TEMAT015) | 90 |

| LX | PVC 1 | Polyurethane Panox / Kevlar + Polyurethane 0,33 (TEMAT169) | 150 |

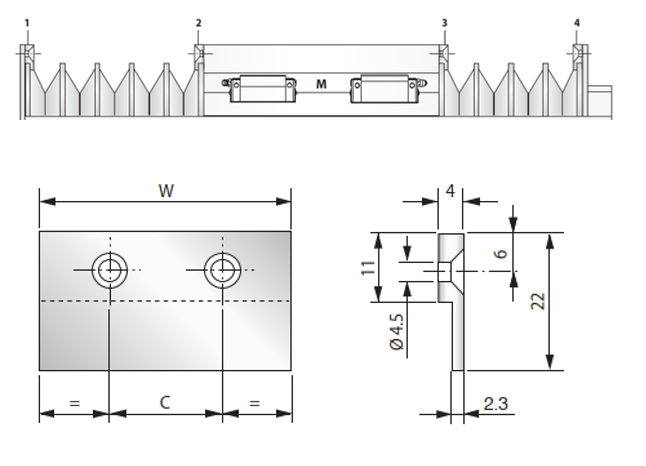

Flanges

Flanges

Flanges Bellows Heat sealed for linear slides

Solution A: Fixing clamps

Solution suitable for harsh work environments and in the presence of refrigerants.

The “M” area must be shielded with sheet metal fixed on the table bench.

Usable for fixing the bellows in all positions 1 – 2 – 3 – 4,

with plate or corner supports prepared by the customer.

| Dimensions solution A | |||

| Rails | W | C | No. HOLES |

| 15 | 52 | 26 | 2 |

| 20 | 57 | 29 | 2 |

| 25 | 63 | 32 | 2 |

| 30 | 68 | 34 | 2 |

| 35 | 72 | 36 | 2 |

| 45 | 83 | 28 | 3 |

| 55 | 104 | 35 | 3 |

| 65 | 128 | 32 | 4 |

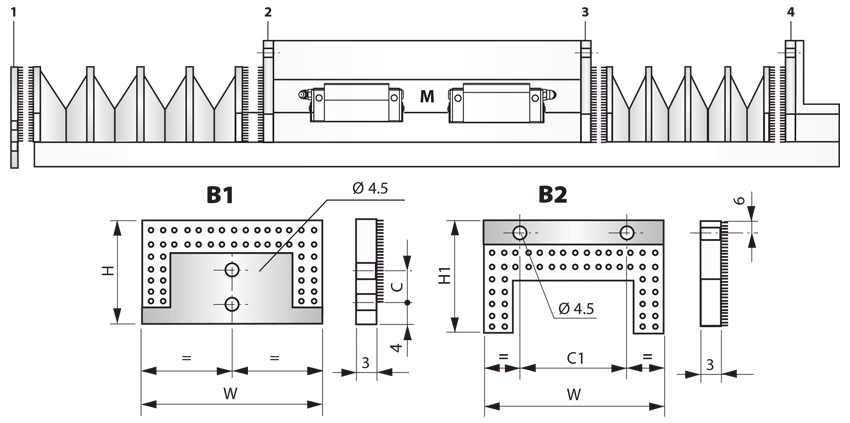

Solution B: Flange fixing with Velcro (B1 and B2)

Solution suitable for dry working environment

The “M” area must be shielded with sheet metal fixed on the table bench

* Standard PVC flanges = B1 and B2

* Flange mounting

Pos. 1

a) Attach the standard type 1 flange to the rail.

b) Join the bellows to the standard type 1 flange by pressing strongly.

Pos. 2-3

a) Fasten the standard type 2 flange to the table or plate with screws.

b) Join the bellows to the standard type 2 flange by pressing strongly.

Pos. 4

a) Secure the standard type 2 flange with screws to the angle prepared by the customer.

b) Join the bellows to the standard type 2 flange by pressing hard.

N.B. The fixings shown in Pos. 1-4 are interchangeable.

| Dimensions solution B | ||||||

| RAILS | W | H | C | H1 | C1 | NO. HOLES |

| 15 | 56 | 36 | 0 | 42 | 26 | 2 |

| 20 | 61 | 40,5 | 8 | 46,5 | 29 | 2 |

| 25 | 67 | 43 | 8 | 46,5 | 32 | 2 |

| 30 | 72 | 51 | 8 | 54 | 34 | 2 |

| 35 | 76,5 | 51 | 18 | 53 | 36 | 2 |

| 45 | 87,5 | 61 | 18 | 62 | 28 | 3 |

| 55 | 108 | 73 | 18 | 69 | 35 | 3 |

| 65 | 132 | 90 | 18 | 86 | 32 | 4 |

Documentation

Bellows Questionnaire for Linear Rails