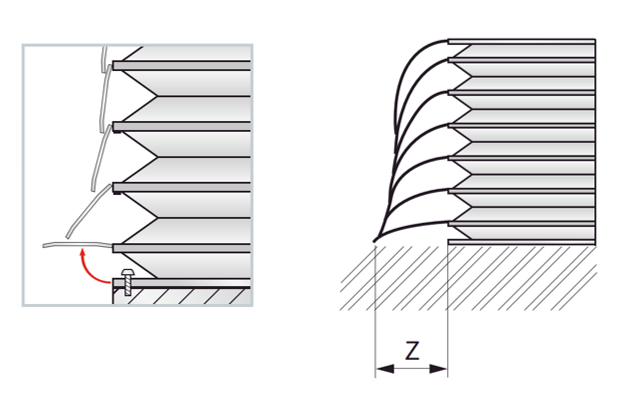

Thermic-welded cover with flexible laminations

Thermic-welded cover with flexible laminations

The P.E.I. thermic-welded standard covers are supplied also with flexible laminations, able to guarantee the same protection as the fixed ones, but they offer more flexibility in matching the supporting plan, thanks to their rotating capability.

PEI thermic-welded flat bellows are made up of:

- Steel laminations: they protect the shield from hot and incandescent chips.

- Bellows: (3) made with fabrics resistant to water, oil, coolants, dust and shavings.

- Supports in PVC: (4) they give rigidity to the entire bellows and are cut to size according to the profile of the customer’s rails.

- Connection flanges (1 and 2) for simple attachment to the machine.

Working position:

– Vertical

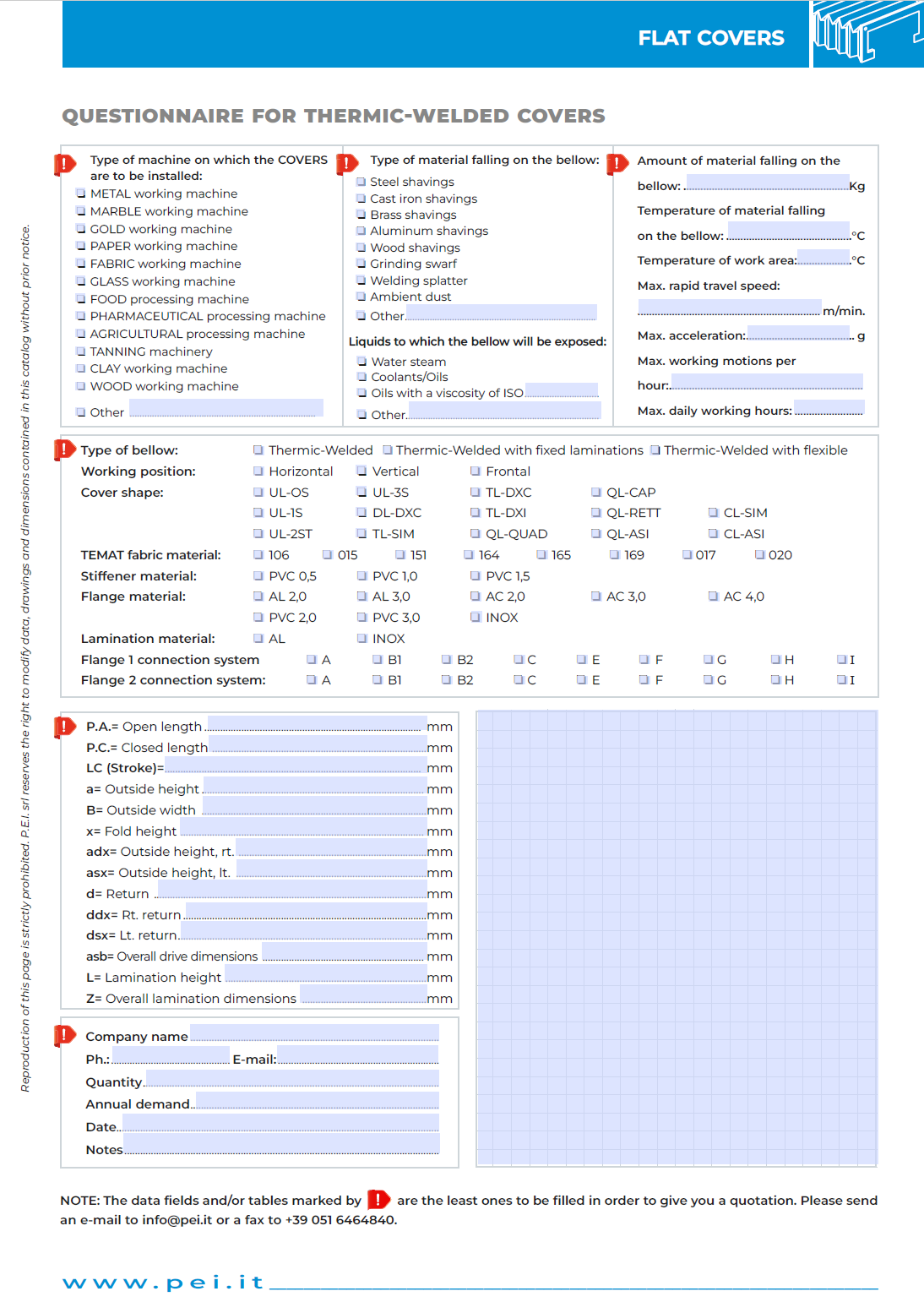

Data

Data

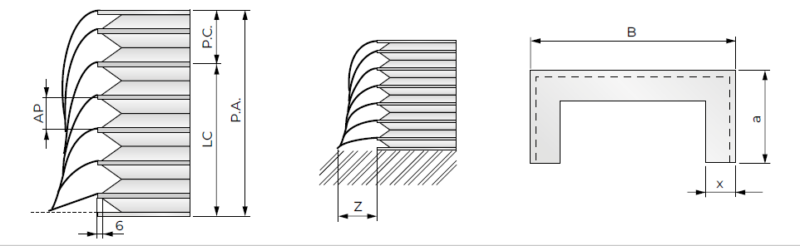

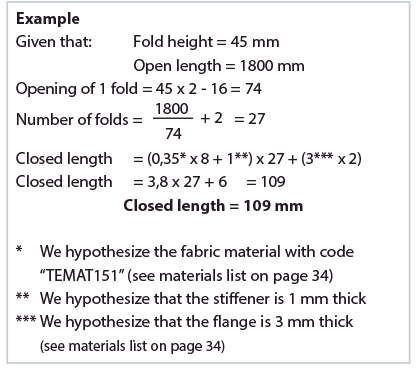

Definition of data for the calculation of the closed length of PEI thermic-welded flat bellows

P.A. = Open length

P.C. = Closed length

AP = Opening of 1 fold

LC (Stroke) = Open length – closed length

B = Bellows width

a = Bellows height

x = Fold height

Overall dimensions of the flexible laminations as a function of the width of the bellow fold

| Bellows crease width = | x (mm) | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| Overall dimensions of the blade above the guide = | Z (mm) | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

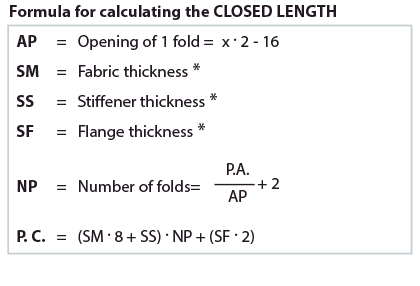

Formulae

Indicative formula for the calculation of the closed length of thermic-welded flat bellows with flexible laminations

Contact our technical office

Example of calculation

* We hypothesize the material of the bellows with the code

“TEMAT151”

** We hypothesize that the thickness of the support is 1 mm

*** We hypothesize that the thickness of the flange is 3 mm

Standard materials

Standard materials

The fabrics selected by PEI have excellent mechanical resistance and resist bending and folding that occur during operation in the machine. They have excellent resistance to petroleum products, oils and strong abrasion, small welding splashes or incandescent material.

Main strength characteristics of the bellows materials:

| Fabric material code | Description | Thickness (mm) | Heat resistance | Primary resistance characteristics | ||||

| Visible side | Fabric insert | Internal side | Momentary contact °C | Continuous | ||||

| min. °C | max. °C | |||||||

| TEMAT 106 | Ptfe | Polyester | 0,30 | +200 | -30 | +120 | Excellent resistance to oils and chemical products. No adhesive surface. Low friction coefficient. Excellent chemical inertia. Excellent resistance to abrasion and bending strength. Mainly used in grinding machines. | |

| TEMAT 015 | Polyurethane | Polyester | Polyurethane | 0,25 | +200 | -30 | + 90 | Excellent resistance to petroleum products, oils and heavy abrasion. Excellent bending strength. |

| TEMAT 151 | Polyurethane | Polyester | Polyurethane | 0,35 | +200 | -30 | + 90 | |

| TEMAT 164 | Polyurethane | Kevlar* | Polyurethane | 0,35 | +350 | -30 | +180 | Excellent resistance to petroleum products, oils and heavy abrasion. Excellent bending strength. Excellent mechanical strength. Kevlar also has excellent shear strength. Normally used when there is heavy mechanical stress, a large amount of sharp shavings, and at high temperatures. |

| TEMAT 165 | Polyurethane | Nomex* | Polyurethane | 0,36 | +300 | -30 | +130 | Excellent resistance to petroleum products, oils and heavy abrasion. Excellent bending strength. Excellent mechanical strength. Good resistance to minor welding splatter or hot material. Widely used in laser cutting machines. Self-extinguishing. |

| TEMAT 169 | Polyurethane | Panox*/Kevlar | Polyurethane | 0,33 | +300 | -30 | +130 | Excellent resistance to petroleum products, oils and heavy abrasion . Excellent bending strength. Excellent mechanical strength. Good resistance to minor welding splatter or hot material. It may be considered as the best fabric on the market for use in laser cutting machines. Self-extinguishing. |

| TEMAT 017 | PVC | Polyester | PVC | 0,36 | +100 | -30 | + 70 | Mainly used around heavy ambient dust, minor splatters of coolant and oil. Also suitable for use around acids. |

| TEMAT 020 | PVC | Polyester | PVC | 0,25 | +100 | -30 | + 70 | |

Other SPECIAL materials are available for specific sectors of use. Ask our technical department

| Materials for the attachment flanges | |||

| Material supports | Description | Thickness (mm) | Notes |

| PVC 05 | PVC | 0,50 | Bellows length (B) up to 300 mm |

| PVC 10 | PVC | 1,00 | Bellows length (B) from 301 to 700 mm |

| PVC 15 | PVC | 1,50 | Bellows length (B) from 701 to 1500 mm |

The PVC support, shaped to measure with the structure of the customer’s rails and welded to each fold of the bellows, gives the heat-sealed bellows excellent stability.

| Flange material | Description | Thickness (mm) |

| AL | Aluminium | 2-3-4-5 |

| INOX | AISI304 | 1-1,5-2-2,5-3 |

| AC | Carbon steel | 1-1,5-2-2,5-3-4-5 |

| PVC | PVC | 1-1,5-2-3 |

The anchoring of the bellows to the machines takes place through the end part of the bellows equipped with rigid flanges in aluminium, stainless steel, carbon steel and PVC.

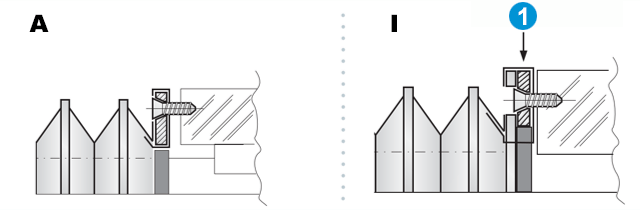

Flanges

Fixing

- = Flange

Attachment flange fixing systems

-Type A et Type I

- Solution with connection flange Type A: Flange covered by the fabric of the bellows (without last support)

- Solution with Type I attachment flange: Painted flange fixed to the last support of the bellows

- Solution with attachment flange in steel, aluminium or PVC sheet

- Shape and drilling according to the customer’s design

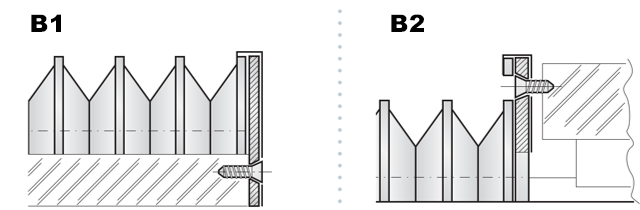

Attachment flange fixing systems

–Type B1 and Type B2

- Solution with connection flange Type B1: Flange that protrudes entirely from the shape of the bellows

- Solution with connection flange Type B2: Flange that protrudes externally with respect to the shape of the bellows

- Solution with attachment flange in steel, aluminium or PVC sheet

- Shape and drilling according to the customer’s design

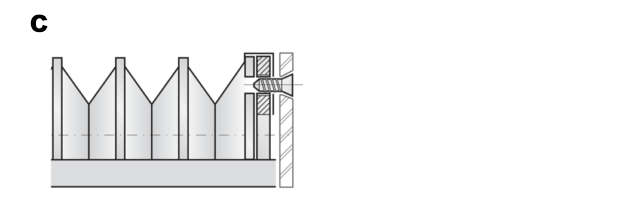

Attachment flange fixing systems

–Type C

- Solution with Type C attachment flange: Painted flange fixed to the last support of the bellows with threaded holes

- Solution with steel sheet attachment flange

- Shape and drilling according to the customer’s design

- The flange holes are threaded

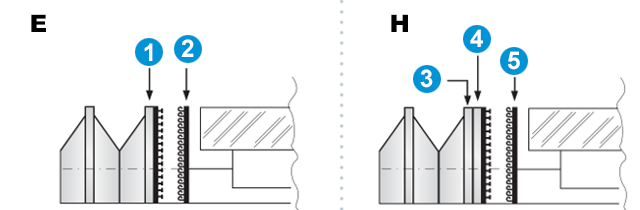

- = PVC cover stiffener

- = Strip of Velcro applied to the machine

- = PVC stiffener

- = Flange

- = Strip of Velcro applied to the machine

Attachment flange fixing systems

–Type E and H

Solution using VELCRO type quick fixing.

The task of the attachment flange is carried out by a PVC support to which VELCRO is applied. A Velcro strip is applied directly to the machine.

This solution offers the following advantages:

- Quick application and removal of the bellows

- Reduced cost

Recommended in dry work environments

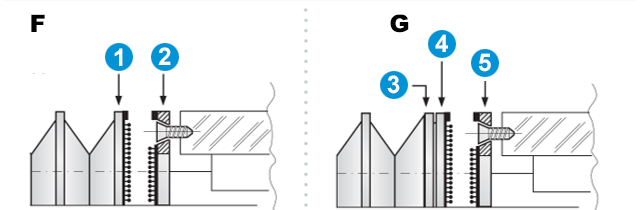

- = PVC stiffener

- = Flange

- = PVC stiffener

- = Flange

- = Counterflange

Attachment flange fixing systems

–Type F and G (Entire fold in PVC )

Solution through HIGH TENACITY quick fixing.

The attachment flange is made of sheet steel, aluminium or PVC, with shape and drilling according to the customer’s design.

This solution offers the following advantages:

- Quick application and removal of the bellows

- Perfect perimeter sealing by applying mousse.

Recommended in a humid working environment

Structures

Structures

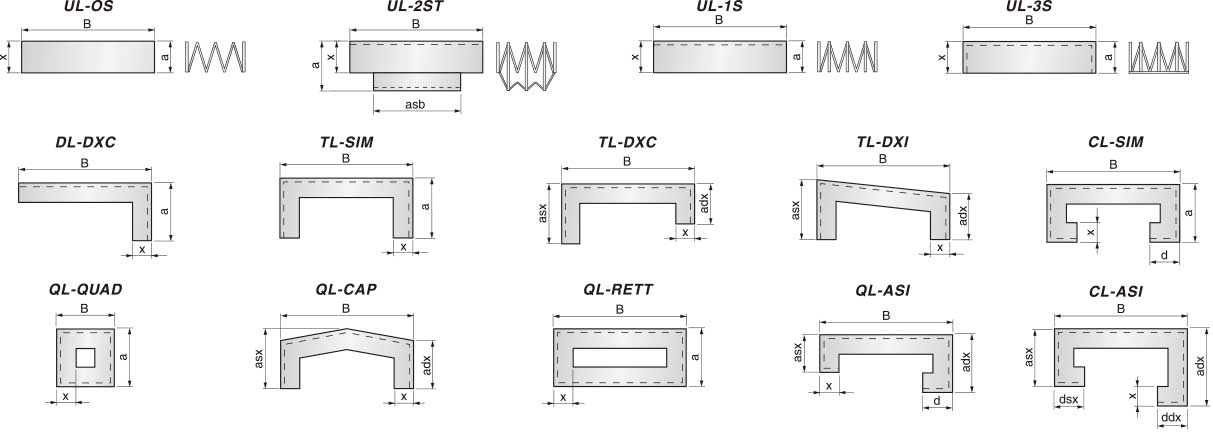

Standard structures for flat thermic-welded bellows

UL-OS = Folding fabric only

UL-2ST = Thermic-welded bellows with two weld seams and pull-out stop inside the bellows

UL-1S = One-sided bellow with PVC supports

UL-3S = One-sided thermic-welded bellows with three welded edges

DL-DXC = Thermic-welded bellows with two welded edges

TL-SIM = Thermic-welded bellows with three welded edges, symmetrical shape

TL-DXC = Thermic-welded bellows with three welded edges, asymmetrical shape

TL-DXI = Thermic-welded bellows with three welded edges, slanted shape

CL-SIM = Thermic-welded bellows with five welded edges, symmetrical shape

QL-QUAD = Thermic-welded bellow, square shape

QL-CAP = Thermic-welded bellow, roof shape

QL-RETT = Thermic-welded bellow, rectangular shape

QL-ASI = Thermic-welded bellows with four welded edge, asymmetrical shape

CL-ASI = Thermic-welded bellows with five welded edge, asymmetrical shape